- FachPack 2019 -

+++ Unpacking +++

A new era for parcels

The parcel opener moves into branches and SMEs

Grünwald, September 2019. Branch operations and online shops will be revolutionised in the future. For the first time, ALS Automatic Logistic Solutions GmbH has developed an 'XS' variant of the automatic parcel opener for small to medium-sized businesses and branch solutions. The semi-automatic JUPI is already worthwhile for a moderate parcel volume of 300 - 1,500 per day.

ALS Automatic Logistic Solutions GmbH, based in Grünwald, near Munich, is known for automatic parcel opening in intralogistics - especially since there is no comparable competitor in the whole of Europe. Now, for the first time, the machine builder has launched a semi-automatic machine for the appropriate parcel quantity of SMEs - due to the great demand.

ALS Automatic Logistic Solutions GmbH, based in Grünwald, near Munich, is known for automatic parcel opening in intralogistics - especially since there is no comparable competitor in the whole of Europe. Now, for the first time, the machine builder has launched a semi-automatic machine for the appropriate parcel quantity of SMEs - due to the great demand.

"It's time for a new era," says Paul Kammerscheid, Managing Director of ALS. "In countless companies, several employees stand every day and still open the many heavy parcels manually by hand knife - for hours a day. This is exactly the problem we are finally solving: with the new JUPI system, employees can devote themselves to more important activities.

"Only one employee is needed to operate the JUPI. After the goods have been delivered, he can use the semi-automatic JUPI to open the parcels chaotically, quickly, efficiently, without cutting employees, cutting up goods or heavy loads, and then turn his attention to other tasks.

The highlight: JUPI uses three electrically operated cutting axes to open the cartons on three of four sides. This 'hinge cut' is particularly popular, as the lid cannot get lost and the return label, for example, remains with the goods until they are finally unpacked. This system offers completely new possibilities, especially for the ever-increasing e-commerce and branch operations in the retail sector - across all industries.

All previous systems from ALS work chaotically as well as fully automatically and are used by the industry giants for automatic picking, returns processing, dispatch optimisation as well as in goods receiving. The automatic systems can open up to 1,200 cartons per hour. The package openers from ALS no longer cut up any goods - unlike hand knives, operated by employees. The efficiency gained, the reduction of rejects and the elimination of the risk of injury to employees are the reasons for the success of the package openers.

The JUPI, which is ready for series production, will be presented to the public for the first time at the FachPack trade fair in Nuremberg on 24-26 September 2019.

- The BOS(S) Year November 2018 -

LIKE A BOSS:

The BOS(S) among automatic parcel openers celebrates its breakthrough!

ALS Automatic Logistic Solutions celebrates its BOS(S) year in 2018: never before have so many automatic parcel openers been manufactured and sold in such a short time. In order to soon meet all intralogistics requests, ALS, based in Grünwald near Munich, is generating more and more solutions. A semi-automatic machine for SMEs is already in the starting blocks.

In addition to the continuous development of new systems, the BOS system (Box Opening System) was produced in unprecedented quantities this year. ALS Automatic Logistic Solutions is now producing much larger batches to meet the increasing demand. The popularity of the BOS is due to both the high flexibility of the cutting patterns provided by the different cutterheads and the promise of undamaged goods. The speed of the process is also remarkable.

The BOS processes (depending on the cut type and carton size) about 600 cartons per hour. Thus, around 2.4 million packages are opened annually with just one machine (in 2-shift operation). The machine thus achieves a comparable capacity of five persons. The investment pays off quickly, as the cost savings are around 90% and the payback period is only about 12 months.

The BOS processes (depending on the cut type and carton size) about 600 cartons per hour. Thus, around 2.4 million packages are opened annually with just one machine (in 2-shift operation). The machine thus achieves a comparable capacity of five persons. The investment pays off quickly, as the cost savings are around 90% and the payback period is only about 12 months.

All parcel openers from ALS are used in incoming goods and returns, in order picking as well as in shipping optimisation. The customers' industry is versatile: "Every company that has a high volume of parcels can use us," says Paul Kammerscheid, managing director of ALS.

So far, ALS has already launched a number of different systems, all of which open a large quantity of parcels chaotically and fully automatically by means of different cutting processes. Damage to the goods is excluded. All systems are developed in such a way that even the most expensive down jacket does not get scratched.

All automatic parcel openers comply with Industry 4.0 standards and can therefore be easily integrated into existing systems. A new parcel opener system is already in the starting blocks. It is intended to offer an excellent solution especially for small and medium-sized enterprises. The semi-automatic system will be presented at the LogiMAT 2019 trade fair (19-21 February 2019) in Stuttgart. "We will also have to directly increase the batch sizes here," says Paul Kammerscheid.

ALS applied for a new patent again this year: The STEN (Anti-Strapping-Engine) package opener can remove plastic strapping at high speed. Another significant success ALS can report in 2018 is the JILL system, which is now ready for sale. The robotic system uses the patented PAM perforation knife to cut the upper, long flaps and additionally the lower, short flaps from the carton. In this way, open cartons can be transported further along the logistics chain without the goods falling out.

- FachPack in Nuremberg (25 - 27.09.2018) -

FachPack 2018: BOS package opener with even smarter slitting technology

Parcel opener BOS decides on the cutting process in future

Munich, 10.08.2018. ALS Automatic Logistic Solutions GmbH from Munich, leading European manufacturer of automatic parcel opening systems, will be presenting the full range of its service portfolio at this year's FachPack in Nuremberg (25 - 27.09.2018), which now includes eleven different cutting machines. ALS will also impress trade visitors with an intelligent modification to its "flagship", the Box Opening System (BOS). Thanks to upstream image processing, this system will in future recognise whether a pack (for example a mesh box) needs to be cut open or not. BOS therefore decides independently in the ongoing production process whether a cardboard box should be cut open or whether it should be sent past the cutter heads unprocessed as a container pack (also possible on a tray). The customer can thus move all packs unsorted and chaotically through the BOS system on the conveyor system.

Munich, 10.08.2018. ALS Automatic Logistic Solutions GmbH from Munich, leading European manufacturer of automatic parcel opening systems, will be presenting the full range of its service portfolio at this year's FachPack in Nuremberg (25 - 27.09.2018), which now includes eleven different cutting machines. ALS will also impress trade visitors with an intelligent modification to its "flagship", the Box Opening System (BOS). Thanks to upstream image processing, this system will in future recognise whether a pack (for example a mesh box) needs to be cut open or not. BOS therefore decides independently in the ongoing production process whether a cardboard box should be cut open or whether it should be sent past the cutter heads unprocessed as a container pack (also possible on a tray). The customer can thus move all packs unsorted and chaotically through the BOS system on the conveyor system.

The cutting machines from ALS can solve almost any application in goods receiving, returns receiving, order picking and dispatch optimisation thanks to the comprehensive options. Depending on the system, the capacity is between 400 and 1,200 cartons per hour. Depending on the package size, the BOS cutting system can open up to 600 shipments per hour or 14,000 units per day. The standard system is able to open parcel sizes from 160 x 140 x 110 mm to 600 x 600 x 400 mm (other sizes possible) without prior sorting five times faster than in manual handling.

BOS automatically detects the dimensions of the respective package via integrated sensors and sets the cut accordingly. A sensor tracks the work sequence and detects the completion of the cutting process so that the next carton can be fed in via the standardised roller conveyor. This means that the system can be easily integrated into existing transport lines. Due to the described advantages in the opening process of cardboard boxes and parcels, the BOS system pays for itself on average in 12 months compared to opening by hand - and tying up the corresponding personnel resources.

BOS automatically detects the dimensions of the respective package via integrated sensors and sets the cut accordingly. A sensor tracks the work sequence and detects the completion of the cutting process so that the next carton can be fed in via the standardised roller conveyor. This means that the system can be easily integrated into existing transport lines. Due to the described advantages in the opening process of cardboard boxes and parcels, the BOS system pays for itself on average in 12 months compared to opening by hand - and tying up the corresponding personnel resources.

Trade visitors will find ALS Automatic Logistic Solutions at FachPack 2018 in Hall 4A, Stand 228.

- Handling Award 2016 for WIM -

WIM Parcel Opener wins this year's Handling Award.

The WIM Parcel Opener from the European market leader ALS receives the "Handling Award

Munich/Stuttgart, October 2016 - at MOTEK 2016, in Stuttgart, the WIM automatic package opener received the Handling Award.

The opening of cartons / parcels without damaging the goods is an ever-increasing time and cost factor in logistics. The solution to this urgent problem is the automatic parcel opener from the European market leader, ALS Automatic Logistic Solutions GmbH, Munich. Their WIM parcel opener has now been awarded the Handling Award. WIM is a fully automatic parcel opener that perforates or cuts a window at the front of a carton. This makes picking easier during manual order picking, speeds up the process considerably and reduces costs significantly.

The opening of cartons / parcels without damaging the goods is an ever-increasing time and cost factor in logistics. The solution to this urgent problem is the automatic parcel opener from the European market leader, ALS Automatic Logistic Solutions GmbH, Munich. Their WIM parcel opener has now been awarded the Handling Award. WIM is a fully automatic parcel opener that perforates or cuts a window at the front of a carton. This makes picking easier during manual order picking, speeds up the process considerably and reduces costs significantly.

If the window is only to be perforated at first, it can be removed later - without tools. This means that cartons can now be prepared by machine in large quantities without damage, e.g. for order picking.

The WIM package opener can be installed in the goods receiving area, behind the miniload or directly in front of the flow rack.

The cartons enter the WIM system chaotically and individually from a roller conveyor. The carton is then clamped and measured (LxWxH). A vacuum suction cup is then placed in the centre of the front side. The carton is tilted backwards to reduce any pressure of the goods on the inner wall of the carton. The vacuum suction cup sucks in the front side to further relieve any pressure that may still be present. The circular knife starts cutting or perforating the previously defined cutting depth and window size.

After cutting, the window is removed by the vacuum cup - later removed without tools when perforating. The carton tilts back into the horizontal position. The carton moves out of the system. Cartons that are unsuitable for the system can be ejected beforehand by an upstream defect detection system.

After cutting, the window is removed by the vacuum cup - later removed without tools when perforating. The carton tilts back into the horizontal position. The carton moves out of the system. Cartons that are unsuitable for the system can be ejected beforehand by an upstream defect detection system.

The system is able to open package sizes from 200 x 200 x 200 mm to 600 x 600 x 400 mm five times faster than manual handling without prior sorting. This enormous throughput significantly reduces the costs in order picking.

Depending on the package size, WIM can open up to 500 cartons per hour or 12,000 units per day. Since the machine does not need any breaks and does not slow down due to exhaustion, it achieves an overall time profitability of 5:1 compared to manual work. The WIM automatic package opener is equipped with Kuka industrial robots and a Siemens PLC 7 control system.

Compared to opening by hand - and tying up the corresponding personnel resources - WIM pays for itself in about ten months. Due to the high economic efficiency of the system, the development of the system is supported by the public sector.

- PRESS RELEASE: Automatic Parcel Opener ZAR -

The automatic package opener ZAR opens up to 900 cartons per hour by side cut!

Munich, 5 November 2015 - shortly after the successful presentation of the automatic parcel opener TOM at FachPack 2015 in Nuremberg, its brother ZAR is now also available.

ZAR completes the range of standardised parcel openers from ALS GmbH, the Europe-wide established specialist for automated parcel openers in goods / returns receiving, order picking and dispatch optimisation.

Opening cartons / parcels without damaging the goods is an ever-increasing time and cost factor in logistics. The booming internet mail order business in particular is confronted with an increasing number of cartons. After the recent development of TOM, another automatic parcel opener with additional methods and procedures now follows. While TOM opens parcels by tape-cutting the upper side of the carton, ZAR can cut open parcels from the side.

Opening cartons / parcels without damaging the goods is an ever-increasing time and cost factor in logistics. The booming internet mail order business in particular is confronted with an increasing number of cartons. After the recent development of TOM, another automatic parcel opener with additional methods and procedures now follows. While TOM opens parcels by tape-cutting the upper side of the carton, ZAR can cut open parcels from the side.

ZAR can open cartons as small as 50 mm high with a single or double-sided cut in a single operation.

This new, automatic package opener ZAR (toothed belt drive) is suitable for lateral cuts and is primarily designed for flat cartons, e.g. samples/specimens, maxi letters made of cardboard, documents, etc.

Optionally, by means of a subsequent 90° turner, the carton in question can be turned in order to be provided with two further lateral cuts in the following station, so that the carton is divided into two parts.

The ZAR pack opener system can open packs from 160 x 140 x 50 mm (LxWxH) quickly and efficiently from the side with a fixed blade without damaging the products inside. ZAR can be used for carton sizes up to a maximum of 800 x 600 x 500 mm and can also be configured in a variety of ways to suit different applications in the field. ZAR can open up to 900 packages per hour efficiently and automatically.

ZAR comes in three versions:

ZAR - M

The model M is made for a uniform width and height of cartons. The lateral longitudinal cut is always made at the same height.

ZAR - H

With the model H the width of the cartons is the same, the carton height can vary, the lateral longitudinal cut can be made at different heights - depending on the carton height.

ZAR - HW

With the HW model, the cartons can vary - in the minimum / maximum values - as desired. The carton size is measured individually for each incoming carton, the vertical belts are set accordingly wide and the knife is moved to the desired height.

The ZAR system performs about 3 times better than manual work and also prevents injuries that cannot be ruled out with manual opening.

The cost saving of machine compared to manual work is approx. 80 %.

Captions:

New parcel opener ZAR from Europe's largest specialist for automatic parcel openers ALS increases the capacity of incoming goods / returns 3-fold.

Motif 1: The innovative parcel opener ZAR from ALS can automatically open cartons from 160 x 140 x 50 mm to 800 x 600 x 500 mm without pre-sorting. The system opens the parcels/cartons on the long side 3 times faster than would be the case manually and thus reduces costs by approx. 80 %.

Motif 2: With the ZAR package opener, cartons are only cut open on the long side - on one or both sides. The main use is for flat cartons, for removing e.g. samples, glasses, documents, spare parts.

Motif 2: With the ZAR package opener, cartons are only cut open on the long side - on one or both sides. The main use is for flat cartons, for removing e.g. samples, glasses, documents, spare parts.

- TOM Tape Only Method -

Open over 7,000 cartons per shift efficiently and automatically using tape cutting! Presented at FachPack.

FachPack premiere: The TOM package opener from ALS opens up to 900 cartons per hour by tape cutting.

Munich/Stuttgart, September 2015 - the TOM automated parcel opener will be presented at FachPack 2015 in Nuremberg. ALS GmbH is thus expanding its range with another standardised parcel opener and establishing itself as the Europe-wide specialist for automated parcel openers in incoming goods and returns.

Opening cartons / parcels without damaging the goods is an ever-increasing time and cost factor in logistics. The booming Internet mail order business in particular is confronted with an increasing number of cartons. In order to open only the longitudinal adhesive tape on the carton, ALS Automatic Logistic Solutions GmbH, Munich, has developed another - worldwide unique - solution for this problem in addition to the successful automatic parcel openers BOS, WIM and ROC: TOM - a fully automatic parcel opener that opens more than 7,000 parcels per shift via tape cut on the upper side of the carton.

This new automatic package opener TOM (Tape-Only-Method) is specially designed for cartons that are sealed lengthwise with adhesive tape only, and which is also only to be cut lengthwise. The system is therefore suitable for relatively homogeneous cartons which, for example, come from a uniform production and are to be reused.

This new automatic package opener TOM (Tape-Only-Method) is specially designed for cartons that are sealed lengthwise with adhesive tape only, and which is also only to be cut lengthwise. The system is therefore suitable for relatively homogeneous cartons which, for example, come from a uniform production and are to be reused.

Many manufacturers, wholesalers and shipping companies send goods in standardised boxes that are sealed with adhesive tape. When these cartons are opened, often only the adhesive tape has to be cut so that they can be reused. This applies to the repacking of goods as well as the later reuse of the cartons in order picking.

The TOM package opener system can open packages from 160 x 140 x 100 mm (LxWxH) quickly and efficiently with a multiple blade on the top side without damaging the products inside. TOM can be used for carton sizes up to a maximum of 600 x 600 x 500 mm and can also be configured in three different ways to suit different use cases in practice.

If boxes that are all the same arrive at the returns entrance, the TOM system can be configured with preset height and width and the boxes can be pushed through via a feeder conveyor belt under the multiple blade. The blades then ensure that even diagonally applied parcel tape is safely cut so that the package is safely opened at the end and the goods inside can be easily removed.

If the goods are received in different carton sizes, TOM can alternatively be configured with variable height detection and thus also open packages that are of different heights.

If the incoming parcels are even less standardised, TOM can not only automatically measure and position the blades to the correct height, but also automatically detect the width of the cartons and perform a width fixation.

In all these cases, up to 900 cartons per hour can be opened safely and reliably in the goods or returns receiving area.

Since the machine does not need any breaks and does not slow down due to exhaustion, it achieves an overall return on investment of 2.5 times that of manual work and also prevents injuries that cannot be ruled out with manual opening.

The cost saving of machine compared to human manual labour is about 80 %.

- ROC Robot Cell -

Automated depalletising, unpacking and further processing of cartons

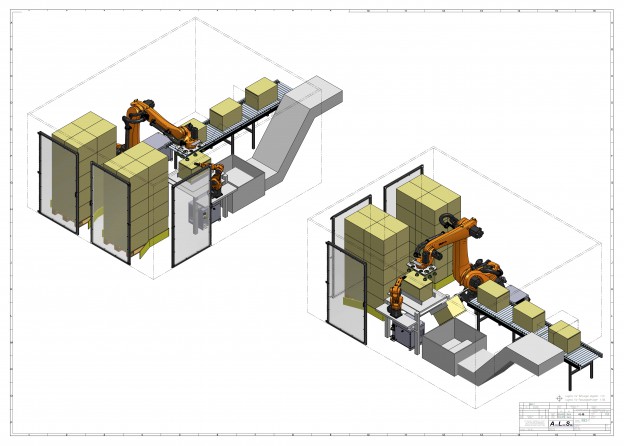

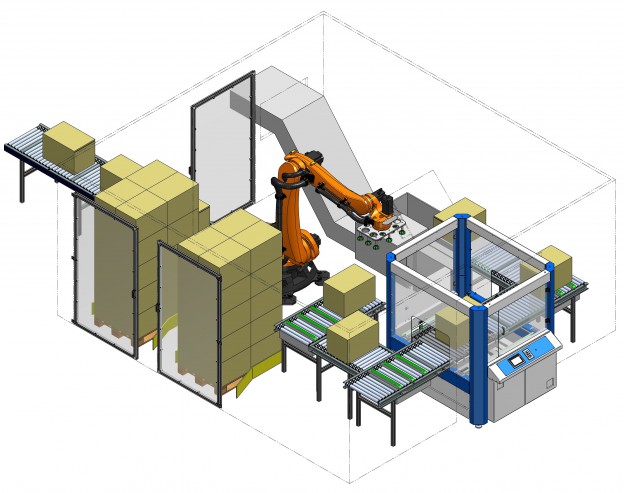

Depalletising robots and pack openers now work hand in hand and can be installed exactly to customer specifications, even in the tightest of spaces.

Depalletising robots and pack openers now work hand in hand and can be installed exactly to customer specifications, even in the tightest of spaces.

In addition to the efficient package opener systems BOS and WIM, ALS Automatic Logistic Solutions GmbH now also offers combinations of package openers and additional industrial robots, specially developed according to customer requirements, which "hand in hand" further automate incoming goods or production. Such a robot cell ROC (one or more robots) is used wherever reliable complete solutions for the unpacking and further processing of goods are required.

Faster processing of the cartons to be emptied through depalletising, automatic opening and subsequent automatic further processing or transfer to subsequent units leads to an enormous increase in efficiency. In addition, the physical strain and risk of injury to the employees is again considerably reduced.

Receiving deliveries, depalletising cartons, opening cartons and then removing the goods and feeding them to production or the warehouse, these are dull and repetitive processes that can ideally be handled by machines. ALS Automatic Logistic Solutions GmbH, which has automated the opening of cartons / parcels, without damaging the goods, with worldwide unique and patented parcel openers, now also supplies complete, customised systems that automate the complete goods receiving process with adapted industrial robots.

Depending on the customer's requirements, such an application consists of depalletisers, pack openers and conveyor systems, as well as subsequent solutions for the further processing of the goods, such as the discharge or removal of the goods or the removal of film sacks - right through to the removal of the used cartons.

By using modern industrial robots, such a ROC(Robot Cell) system can be integrated into existing plants in the smallest possible space and individually adapted to the individual area of application.

A robot cell ROC either contains special cutting knives for the particular application or is connected to the fully automatic package openers BOS or WIM from ALS GmbH and can thus also process chaotic incoming goods quickly and efficiently.

The automatic parcel opener BOS - Box Opening System - uses cutting technology to open parcels and cartons - without presorting - up to 600 units per hour or 14,000 units per day. Several knife variants are available, which allow eight different types of cut and open the cartons in an optimised way for specific further processing.

With its cutting technology, for cutting out a window at one end of the carton, the automated package opener WIM - Windows Method -, offers an optimal solution for picking and packing.

With ROC, a flexible - robot-supported - system is now available, which can be used practically for any requirement, such as goods receipt or production, and can be flexibly adapted to the prevailing needs on site.

Picture material

ROC is a tailor-made product consisting of depalletiser, pack opener and conveyor systems as well as solutions such as e.g. discharge, removal of goods, peeling off of film sack - up to carton disposal.

ROC as a customised robot cell for depalletising and further processing (steps 1 and 3), BOS for opening the cartons (step 2).

- BOS Box Opening System -

Automatically open 600 cartons per hour - even with chaotic goods receipt

Within 6 seconds, the BOS system from ALS Automatic Logistic Solutions GmbH can open a carton. Without damaging the contents, of course. This is the most advanced and highly automated technology in goods receiving available worldwide.

Within 6 seconds, the BOS system from ALS Automatic Logistic Solutions GmbH can open a carton. Without damaging the contents, of course. This is the most advanced and highly automated technology in goods receiving available worldwide.

With six different cutting types and eight cutting depths of the BOS system, logistics managers can now increase efficiency in goods receiving by up to 70 %. At the same time, the latent risk of injury to employees when opening by hand is reduced to zero.

The special technology, which has been developed and tested by specialists for several years now, also excludes any damage to the goods. Regardless of whether there are plastic films with goods or other cartons, for example retail cartons, behind the walls of the outer carton to be opened, the BOS system opens the outer carton in question and not the goods.

Interested parties can inform themselves at any time about the possible applications in the areas of incoming goods, returns, order picking and outgoing goods. ALS automatic parcel openers are suitable for use in industry, fulfilment, shipping and wholesale.

- WIM Windows Method -

Rational and damage-free carton opening!

The WIM Parcel Opener opens cartons at the end face

The WIM Parcel Opener opens cartons at the end face

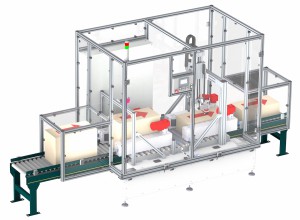

Quickly opening cartons / parcels without damaging the goods often means an elaborate time and cost factor in logistics. The booming internet mail order business in particular is confronted with an increasing number of cartons. Against this background, ALS Automatic Logistic Solutions GmbH, Munich, has brought a unique solution to the market: a fully automatic parcel opener, which carries out the process of opening at the front of cartons in the form of a window. This makes picking easier during manual order picking.

The new WIM (Window Method) package opener from ALS has the option of automatically cutting or perforating a window in the front of the carton if the window is to be removed later - without tools.

This means that cartons can now be prepared by machine in large quantities without damage, e.g. for order picking.

The WIM package opener can be installed in the goods receiving area, behind the miniload or directly in front of the flow rack.

The cartons enter the WIM system chaotically and individually from a roller conveyor. The carton is clamped and measured (LxWxH). A vacuum suction cup is placed in the centre of the front side. The carton is tilted backwards to reduce any pressure of the goods on the inner wall of the carton. The vacuum suction cup sucks in the front side to further relieve any pressure that may still exist. The circular knife starts cutting or perforating the previously defined cutting depth and window size.

After cutting, the window is removed by the vacuum cup - later removed without tools when perforating. The carton tilts back into the horizontal position. The carton moves out of the system.

Cartons that are unsuitable for the system can be rejected beforehand by an upstream defect detection system.

The system is able to open pack sizes from 200 x 200 x 200 mm to 600 x 600 x 400 mm five times faster than manual handling without prior sorting.

Depending on the package size, WIM can open up to 500 cartons per hour or 12,000 units per day. Since the machine does not need any breaks and does not slow down due to exhaustion, it achieves an overall time profitability of 5:1 compared to manual work. This means that the system pays for itself in about ten months compared to opening by hand - and tying up the corresponding personnel resources. Due to this high economic efficiency of the system, the development of the system is supported by the public sector.

- BOS Box Opening System -

New parcel opener from ALS increases capacity 5-fold

Munich in September 2013. Opening parcels quickly and securely often means an elaborate time and cost factor in logistics. For example, the booming internet mail order business is confronted with an increasing number of returns. As a recent study by the market research institute Dialego shows, the return rate for outerwear in 2011 was almost 75 percent! Even at the mail-order guru Zalando, the rate is well over 50 percent. Against this background, ALS Automatic Logistic Solutions GmbH, Munich, together with the developer Bernhard Hörl, has launched a system solution that is unique in Europe so far: a fully automatic parcel opener that carries out the process of opening a wide variety of packaging formats five times faster than by hand.

Munich in September 2013. Opening parcels quickly and securely often means an elaborate time and cost factor in logistics. For example, the booming internet mail order business is confronted with an increasing number of returns. As a recent study by the market research institute Dialego shows, the return rate for outerwear in 2011 was almost 75 percent! Even at the mail-order guru Zalando, the rate is well over 50 percent. Against this background, ALS Automatic Logistic Solutions GmbH, Munich, together with the developer Bernhard Hörl, has launched a system solution that is unique in Europe so far: a fully automatic parcel opener that carries out the process of opening a wide variety of packaging formats five times faster than by hand.

The innovative Box Opening System from ALS has four different cut types. The complete cut creates a removable lid, whereas with the hinge cut one side of the package remains closed so that the package can be conveniently opened. If the packs are initially to be transported closed within the company, BOS offers the perforation cut. In this case, a small cardboard web remains at each corner. This protects the goods until the lid is completely cut off by hand. In addition, the BOS can open longitudinally glued folding cartons using a tape cut along the entire length of the package. The way in which the system cuts the package can be individually selected via a control display. The cutting depth can also be continuously adjusted between 4 and 11 millimetres so as not to damage the goods.

The system is able to open package sizes from 160 x 140 x 120 mm to 600 x 600 x 400 mm without prior sorting five times faster than in manual handling. The BOS automatically detects the dimensions of the respective package via integrated sensors and sets the cut accordingly. A laser tracks the work sequence and detects the respective completion of the cutting process so that the next carton can be fed in via the standardised roller conveyor. This means that the system can be easily integrated into existing transport lines.

Depending on the parcel size, the BOS can open up to 600 items per hour or 14,000 units per day. Since the machine does not need any breaks and does not slow down due to exhaustion, it achieves an overall time profitability of 5:1 compared to manual work. This means that the system pays for itself in less than ten months on average compared to opening by hand - and tying up the corresponding personnel resources. Due to this high economic efficiency of the system, the development of the system was funded by the Central Innovation Programme for SMEs (ZIM) of the Federal Ministry of Economics and Technology.