WIM cuts or perforates a window out of chaotic incoming goods - up to 500 cartons / hour. The performance is about 5 times that of manual processing. The parcels can then be brought into the warehouse with the pick window and are prepared for picking.

"There are actually only positive effects: The new process sequence conserves the employee's capacities, prevents cuts and, last but not least, protects the carton contents." - Logistics planning/control department manager, e-commerce customer

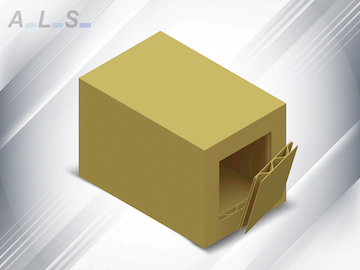

The automatic package opener - WIM (window method) is used where cartons are to be opened at the front; e.g. when picking goods manually.

The automatic package opener - WIM (window method) is used where cartons are to be opened at the front; e.g. when picking goods manually.

WIM cuts or perforates with our patented special knife PAM at the desired cutting depth.

Occupational safety

Compared to manual opening, WIM does not need a break, nor does the speed drop over time - and there are no breakdowns due to strikes, illness or holidays. Damage to the goods during opening is excluded.

Procedure

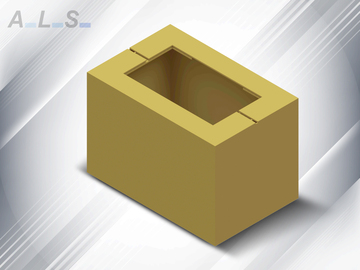

Cartons are fed to WIM individually. The carton is clamped and measured (LxWxH). Then the carton is tilted backwards to reduce the pressure of the goods on the inner wall of the carton. In addition, the front of the carton is pulled outwards by a vacuum suction cup to further relieve the pressure on the inner wall of the carton.

A predefined window is then perforated or cut into the carton. The cutting depth can be preset via the control panel display.

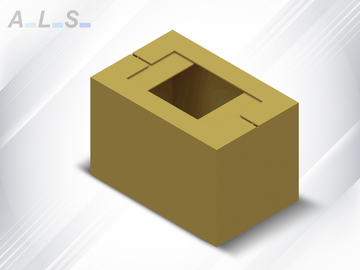

After perforating, the window can - at a later stage - be completely detached and removed without tools. When cutting, the window is removed from the box directly after the cut by the vacuum suction cup.

In the next step, the carton is brought back into a horizontal position and moves out of the WIM system.

Package sizes

The standard WIM handles pack sizes from L x W x H: 200 x 200 x 200 mm to 600 x 600 x 400 mm - without prior sorting.

Integration

Thanks to the standardised roller conveyor, WIM can be easily integrated into existing transport lines with depalletisers, defect detection systems, robots, etc. WIM is ideal for use in order picking and goods receiving.